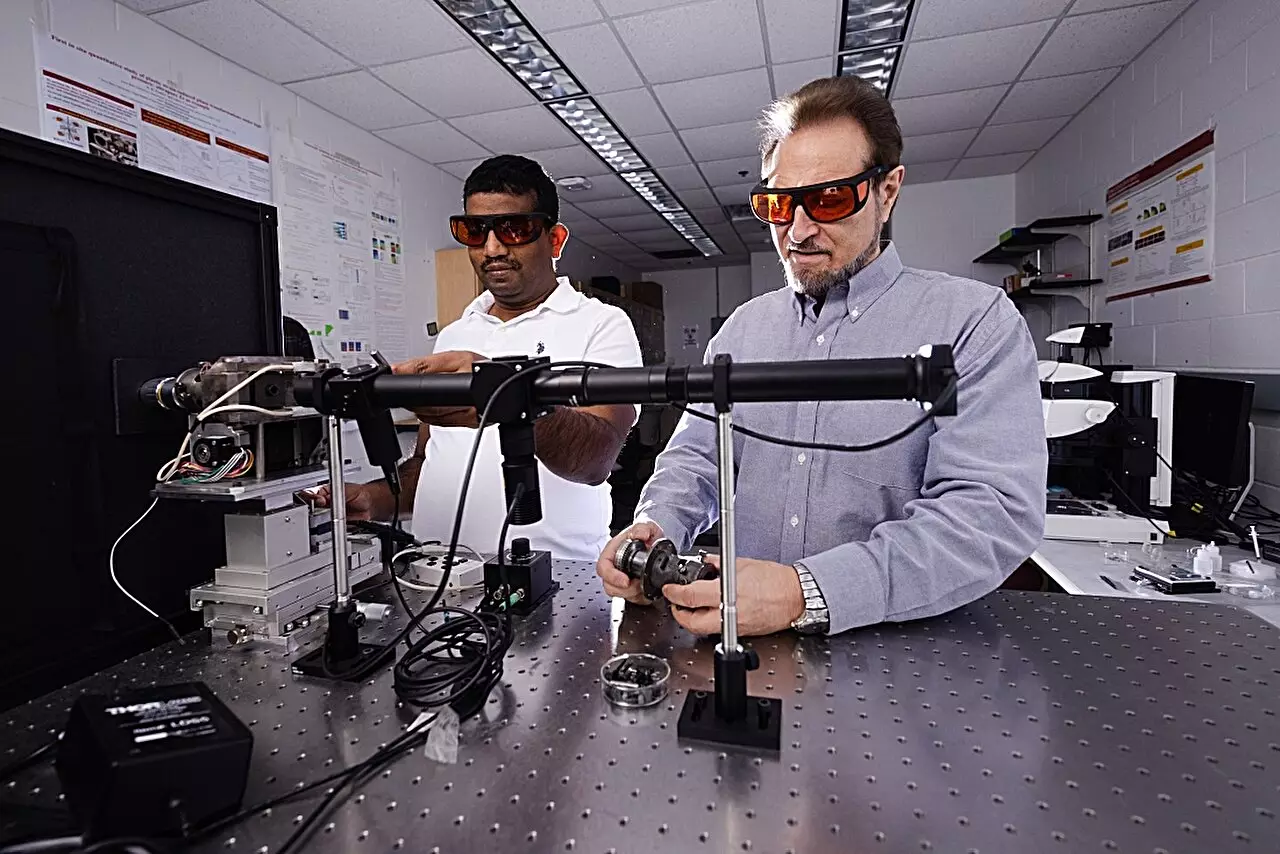

In the year 1999, Valery Levitas made a pivotal decision that would drive his research forward: he relocated from Europe to the United States, bringing along a revolutionary tool known as a rotational diamond anvil cell. This sophisticated instrument allows for the manipulation of materials under extreme pressures and shear forces, enabling researchers to observe phenomena in situ—directly within the experimental setting. This unique capacity to investigate how materials behave under significant stress adds profound depth to material science, physics, and engineering. Levitas, who holds a distinguished position in engineering at Iowa State University, underscores the interdisciplinary nature of this work, bridging mechanics, applied mathematics, and material science.

Exploring the properties of materials, especially at the atomic level, has always fascinated scientists. With this tool, Levitas and his research group focus not only on theoretical predictions regarding material behavior under pressure but also on the practical implications of their findings. This dual focus leads to transformative insights about crystal structures and their resultant properties. One striking question they seek to answer is how materials, such as silicon, may behave differently under conditions of pressure and shear deformation—a combination that had not been extensively studied prior to their research.

In a recent publication by Levitas and his collaborators in Nature Communications, they unveil groundbreaking findings concerning silicon, one of the most critical materials in the electronics industry. Their research demonstrates that silicon undergoes unique phase transformations under conditions involving plastic deformations in addition to high pressures. This distinction sets their work apart from previous studies where the focus was predominantly on pressure alone.

The research targets three distinct particle sizes of silicon—ranging from a millionth of a meter to 100 billionths of a meter—subjected to innovative strains using the rotational diamond anvil cell. The significance of this approach lies in its ability to produce “plastic strain-induced phase transformations,” which are markedly different from transformations induced merely by pressure. The experiments revealed that silicon’s transition from the “Si-I” crystal phase to the “Si-II” phase could occur at remarkably reduced pressures of 0.3 gigapascals, a stark contrast to the 16.2 gigapascals required for transformation under pressure alone.

This is a noteworthy achievement, as Levitas points out that one of their principal objectives is to lower the pressure needed for phase transformations—a feat that broadens the scope for industrial applications. By conducting research in what is usually overlooked as very low pressure territory, they are uncovering possibilities for manipulating materials in practical and economically viable ways.

The relevance of these findings extends beyond theoretical exploration; they hold substantial implications for various industries. Levitas emphasizes that the primary goal of their research is not merely to shape or resize material samples but to alter their microstructure. The significance of microstructural changes cannot be overstated, as they can invoke new phase transitions that lead to materials with enhanced or novel properties. The study draws attention to seven distinct phases of silicon, each with potential industrial applications ranging from electronics to optics.

The process of retrieving desired nanostructured phases or composites with optimal properties could enable industries to harness silicon’s capabilities more effectively. The striking advantage of this technique is its capability to induce traditionally high-pressure phase transformations at significantly lower pressures, thereby making the process more feasible for industrial application. Levitas notes that while working with extremely high pressure isn’t practical for many industrial settings, the introduction of plastic deformations provides a pathway to access these advanced material properties with reduced energy and economic costs.

As Levitas reflects on over two decades of theoretical and experimental inquiry into material behaviors, he acknowledges that expectations regarding silicon’s unusual responses were instrumental in propelling the research forward. This work emphasizes the importance of interdisciplinary approaches in material science, potentially heralding a new era of innovation that leverages the unique properties of materials under extreme conditions.

By challenging traditional notions surrounding material transformations, Levitas and his team are poised to make significant contributions to the field, paving the way for applications that could transform the electronics industry and beyond. Their groundbreaking findings encourage further exploration, stimulating curiosity and investigation into the myriad possibilities that await at the intersections of science and engineering.

Leave a Reply

You must be logged in to post a comment.