In recent years, ultra-high-performance concrete (UHPC) has emerged as a material of choice for modern construction, recognized for its remarkable strength and longevity. Yet, the complexity of its behavior when combined with fiber-reinforced polymers (FRP) has posed significant challenges for engineers. A new study spearheaded by researchers from Huazhong University of Science and Technology and Southern University of Science and Technology has unveiled a pioneering stress-strain model, aiming to bridge the knowledge gap in understanding the performance of FRP-confined UHPC. This innovative approach does not merely represent a slight refinement of existing models; rather, it endeavors to transform the landscape of structural engineering by addressing critical misunderstandings in compressive behavior.

Traditionally, design models for concrete have largely centered around normal-strength concrete (NSC), with FRP methodologies deriving their assumptions from this foundational knowledge. However, applying these models to UHPC has proven inadequate. As engineers strive to advance structural designs, it becomes essential to tailor models that specifically consider the unique characteristics of UHPC, thereby ensuring mechanical fidelity in real-world applications.

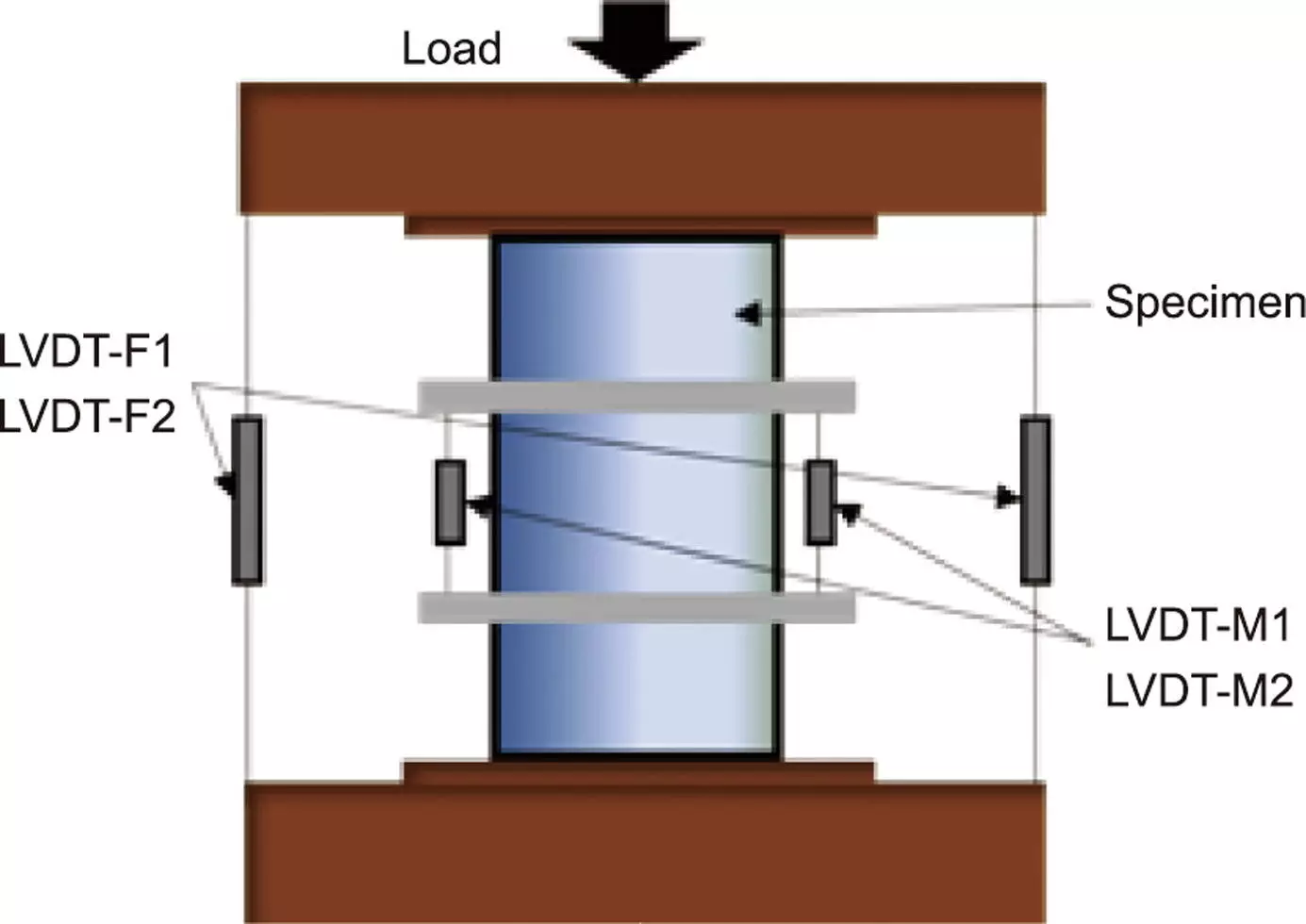

The study conducted by S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie employed a set of experiments targeting the compressive behaviors of UHPC encased within FRP. One of the key outcomes of their research was identifying how the commonly accepted premise of stress-path independency—a principle effective for NSC—fails spectacularly when applied to UHPC. The presence of significant diagonal cracks during FRP confinement led to irregular lateral expansions, reducing the effective confining pressure from the FRP on the UHPC. This revelation necessitated a reevaluation of prevailing assumptions within concrete compressive modeling.

Through rigorous experimentation, the team was able to observe and document these non-linear behaviors, unveiling how such discrepancies in material interaction impact overall performance. By reshaping the initial theoretical frameworks, they crafted a novel analysis-oriented model that appreciates the stress-path dependency. The introduction of a new equation addressing the confining pressure gap marked a significant leap in understanding how UHPC resists compressive forces.

The research did not stop at the theoretical formulation; it proceeded to rigorously validate the new model against a comprehensive database of test outcomes. The resulting predictive capabilities of the model demonstrated a high degree of fidelity in representing the stress-strain behavior of FRP-confined UHPC. This enhancement leads to substantive benefits in terms of safety and reliability for engineers tasked with designing structures that utilize UHPC.

The implications of this research are far-reaching. As construction methodologies evolve, the enhanced understanding and predictive ability afforded by this model will guide engineers in making informed decisions that prioritize structural integrity. The accurate representation of UHPC’s performance properties will empower engineers to explore new designs and innovations, moving beyond traditional limits and creating infrastructure capable of withstanding a multitude of stresses.

With traditional models proving inadequate, this pioneering study signals a transformative moment for both structural engineering and material sciences. It facilitates a deeper comprehension of the intricacies of UHPC, particularly when confined by FRP. By accommodating stress-path dependencies and offering tools that are attuned to the challenges posed by high-performance materials, researchers and engineers can significantly improve the safety and effectiveness of construction projects.

Importantly, this research encourages ongoing dialogue in the field, inspiring future investigations that will continue to push the boundaries of concrete science. Enhanced structural reliability and performance are not just beneficial but critical as global infrastructure faces increasing demands. As the construction industry adapts to these challenges, innovations derived from this new model will likely set standards for future practices and applications in high-performance concrete technology. Thus, the insights yielded from this groundbreaking study promise to resonate within the field for years to come, fostering advancements that strengthen our built environment.

Leave a Reply

You must be logged in to post a comment.