The advancement of technology across various sectors, including energy and defense, heavily relies on the development of robust materials capable of enduring extreme environmental challenges. These materials must be designed to withstand harsh conditions—ranging from intense pressure and temperature to corrosive environments. To create next-generation materials that are not only resilient but also economically feasible and environmentally sustainable, it’s crucial to delve into the fundamental behaviors of materials at the atomic level, especially under pressure.

Recent findings from the Lawrence Livermore National Laboratory (LLNL) shed light on the complex behavior of zirconium, a metal known for its robust properties. Researchers conducted compression tests on single crystal samples of zirconium, revealing unexpected deformation patterns under high-pressure conditions. This groundbreaking research, disseminated in notable scholarly journals, highlights the necessity of understanding the mechanisms through which materials respond to extreme stresses.

Zirconium alloys are notably significant in the nuclear industry, primarily due to their high structural integrity and minimal neutron interference. Understanding their deformation under stress could lead to major advancements in how these materials are utilized in high-pressure scenarios, such as in nuclear reactors and advanced military applications.

Insights into Microscopic Mechanisms

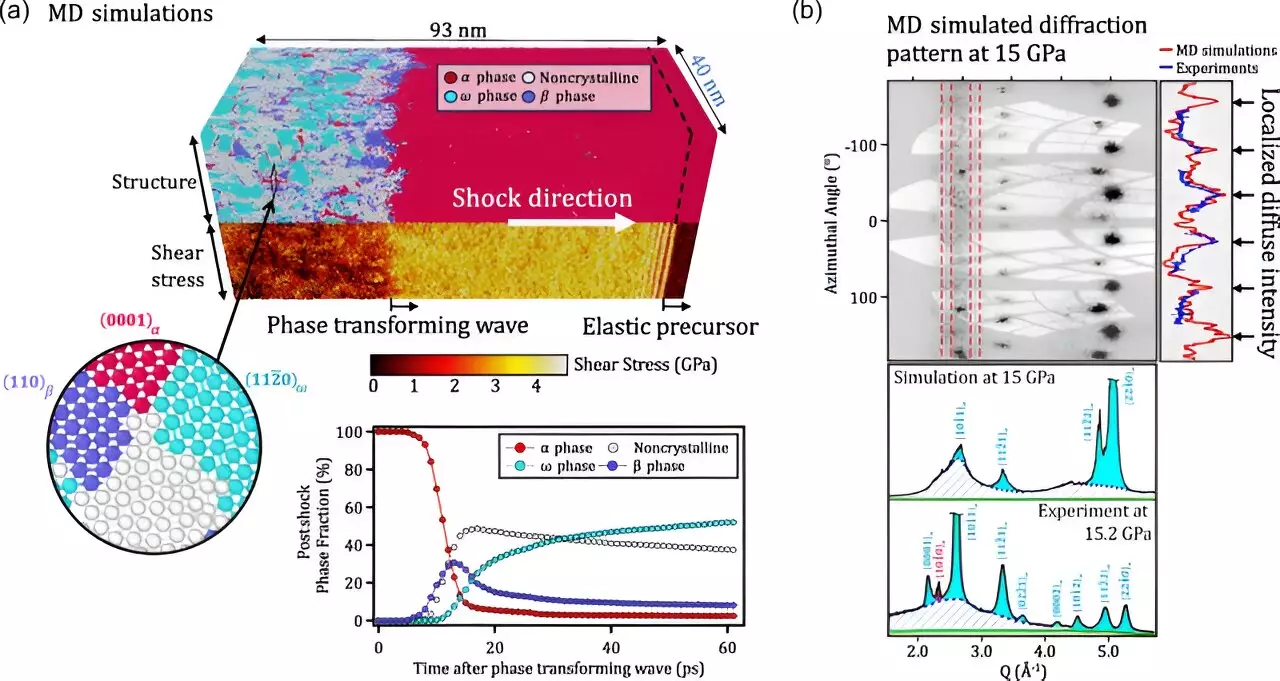

The study conducted at LLNL emphasizes the importance of microstructural analysis. Under high stress, materials typically experience plastic deformation, where defects, termed dislocations, move along designated crystallographic planes. However, zirconium exhibits added complexity; its crystal structure transforms when subjected to pressure, prompting a reevaluation of existing deformation models.

Lead researcher Saransh Soderlind highlights that recognizing the specific crystallographic orientations in which zirconium deforms can lead to significant advances in predictive modeling for material performance. This knowledge becomes vital for engineers and scientists who are tasked with innovating materials that can function in extreme conditions.

One of the standout methodologies applied in this research was femtosecond in-situ X-ray diffraction. This technique enabled scientists to observe the dynamic behavior of zirconium at high compression levels in real-time. For the first time, the team identified atomic disorder within an elemental metal, unveiling a spectrum of pathways for structural transformation. This innovative approach offered unique insights that were absent in previous studies of polycrystalline zirconium, accentuating the novelty of their findings.

Furthermore, the research incorporated advanced simulations utilizing machine learning algorithms, corroborating their experimental findings and painting a more robust picture of the deformation processes at work.

The intricate behaviors observed in zirconium under extreme conditions signal a pivotal shift in material science. These insights extend beyond zirconium, suggesting that similar complexity may be present in other materials subject to high pressure. As scientists continue to explore these phenomena, it is likely that new, innovative materials will emerge, impacting the fields of nuclear energy and beyond. The continual study of materials at the atomic level not only enhances our understanding but also drives the quest for cost-effective, lightweight, and durable materials essential for modern technology.

Leave a Reply

You must be logged in to post a comment.