Recent advancements in soft robotics, particularly within the realm of fabric-based soft pneumatic actuators (FSPAs), illustrate a significant leap in technology that merges theoretical foundations with practical applications. FSPAs are designed to respond to variations in air pressure, allowing them to change shape and perform movements that mimic biological systems. Unlike traditional rigid actuators, these soft devices exemplify safety and versatility, making them highly effective for applications ranging from wearable technology to robotic grippers. Their inherent adaptability allows them to navigate and interact with diverse environments, making them integral to advancements in robotics that require a gentle touch.

Despite their promising capabilities, the design and production of FSPAs are fraught with challenges. Specifically, ensuring these actuators deform predictably under pressure has historically involved time-consuming trial-and-error methodologies. However, a recent study led by researchers from Toyota Central R&D Labs and Toyota Motor Engineering & Manufacturing North America seeks to revolutionize this field by employing Turing patterns—an innovative concept initially proposed by mathematician Alan Turing in 1952.

Alan Turing’s work on morphogenesis describes how natural patterns—such as those seen in animal markings—arise from developmental processes influenced by reaction-diffusion mechanisms. These patterns emerge through interactions between two substances: one promoting growth and another inhibiting it. The application of Turing’s theories to FSPAs offers a novel approach to designing the surface textures of these actuators, allowing them to achieve controlled movement through optimized shapes and materials.

Dr. Masato Tanaka and Dr. Tsuyoshi Nomura spearheaded this research endeavor, emphasizing their objective to craft pneumatic actuators that operate efficiently without reliance on costly materials or complex technologies. By integrating Turing patterns into the design of FSPAs, the team aims to enhance the actuators’ morphing capabilities while simplifying the manufacturing process.

One of the primary hurdles in developing FSPAs is finding materials that can inflate and deform predictably. Historically, the sector has employed isotropic materials with uniform properties, but such materials often result in inconsistent behavior when pressure is applied. In an ambitious response to this problem, the research team utilized a gradient-based orientation optimization method to manipulate the structural properties of the fabric membranes.

By designing these membranes with anisotropic materials—where properties vary based on orientation—the researchers were able to generate complex patterns that directly influence the actuator’s movement. This technique not only enhances the performance of the actuators but also significantly reduces the material waste associated with traditional production methods. Dr. Yuyang Song elaborated on the optimization of material orientation and its pivotal role in ensuring that the actuators deform as intended when subjected to pneumatic pressure.

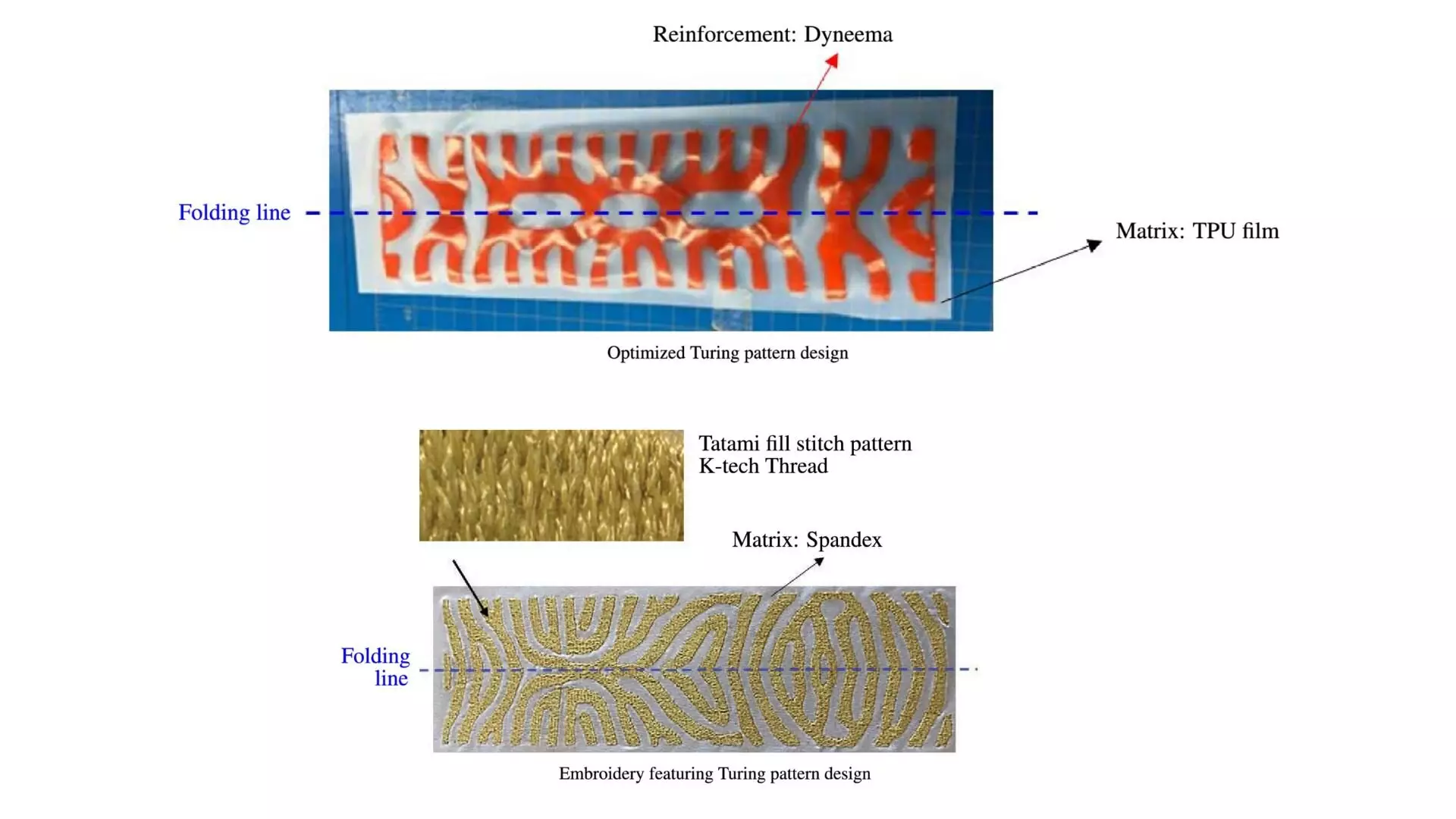

The successful application of Turing patterns is dependent on the efficacy of the fabrication techniques employed. The research team explored two innovative methodologies: heat bonding and embroidery. Heat bonding involves layering a rigid material like Dyneema with a softer fabric such as TPU film, which allows the Turing patterns to be laser-cut and adhered. Conversely, the embroidery technique incorporates stiff threads into the fabric, creating sections of varying stiffness to facilitate movements that are both nuanced and controlled.

Both techniques are lauded for their scalability and cost-effectiveness, opening avenues for large-scale production. As Dr. Song notes, this approach not only streamlines the production process but also diminishes the costs associated with actuator fabrication—a critical consideration for mass-market applications.

As the research team continues to refine their methodologies, the implications of integrating Turing patterns into soft robotics become increasingly profound. Future inquiries are aimed at combining these patterns with state-of-the-art materials, such as shape memory alloys and electroactive polymers, which promise to further enhance the dynamics of FSPAs.

Additionally, the team envisions employing techniques like 3D printing and automated weaving to bolster efficiency and precision in fabrication. These developments could dramatically reshape the landscape of soft robotics, paving the way for more sophisticated applications in healthcare, assistive technologies, and beyond.

The integration of Turing patterns into the design of fabric-based soft pneumatic actuators heralds a new era in soft robotics, characterized by advanced design capabilities and the promise of practical, real-world applications. As research continues, the potential for creating more dynamic, responsive, and user-friendly robotic systems may soon become a tangible reality.

Leave a Reply

You must be logged in to post a comment.