The University of Toronto Engineering researchers have developed a groundbreaking catalyst that efficiently converts captured carbon into valuable products, despite the presence of contaminants that typically degrade the performance of existing catalysts. This discovery represents a significant advancement in the field of carbon capture and storage, offering more economically feasible techniques that can be integrated into current industrial processes.

Professor David Sinton, a senior author on the paper published in Nature Energy, emphasizes the importance of finding cost-effective ways to capture and upgrade carbon emissions from industries like steel and cement manufacturing. While low-carbon electricity generation has seen substantial improvements, sectors that produce significant CO2 emissions still require innovative solutions. The development of this new catalyst opens up opportunities for transforming captured carbon into usable fuels and chemical feedstocks.

The researchers utilize electrolyzers to facilitate the conversion of CO2 and electricity into valuable carbon-based molecules such as ethylene and ethanol. These products can be commercialized as fuels or utilized as building blocks for various consumer goods. The catalyst within the electrolyzer plays a critical role in accelerating the conversion reaction and minimizing the production of unwanted byproducts that can diminish efficiency.

While many catalysts have been designed to operate effectively with pure CO2 feeds, real-world carbon streams often contain impurities that can interfere with the conversion process. Sulfur oxides, such as SO2, are particularly problematic as they can bind to the catalyst surface, reducing reaction sites and promoting the formation of undesirable chemicals. Dealing with impurities like SO2 has been a major challenge for catalyst designers striving to maintain high conversion efficiency.

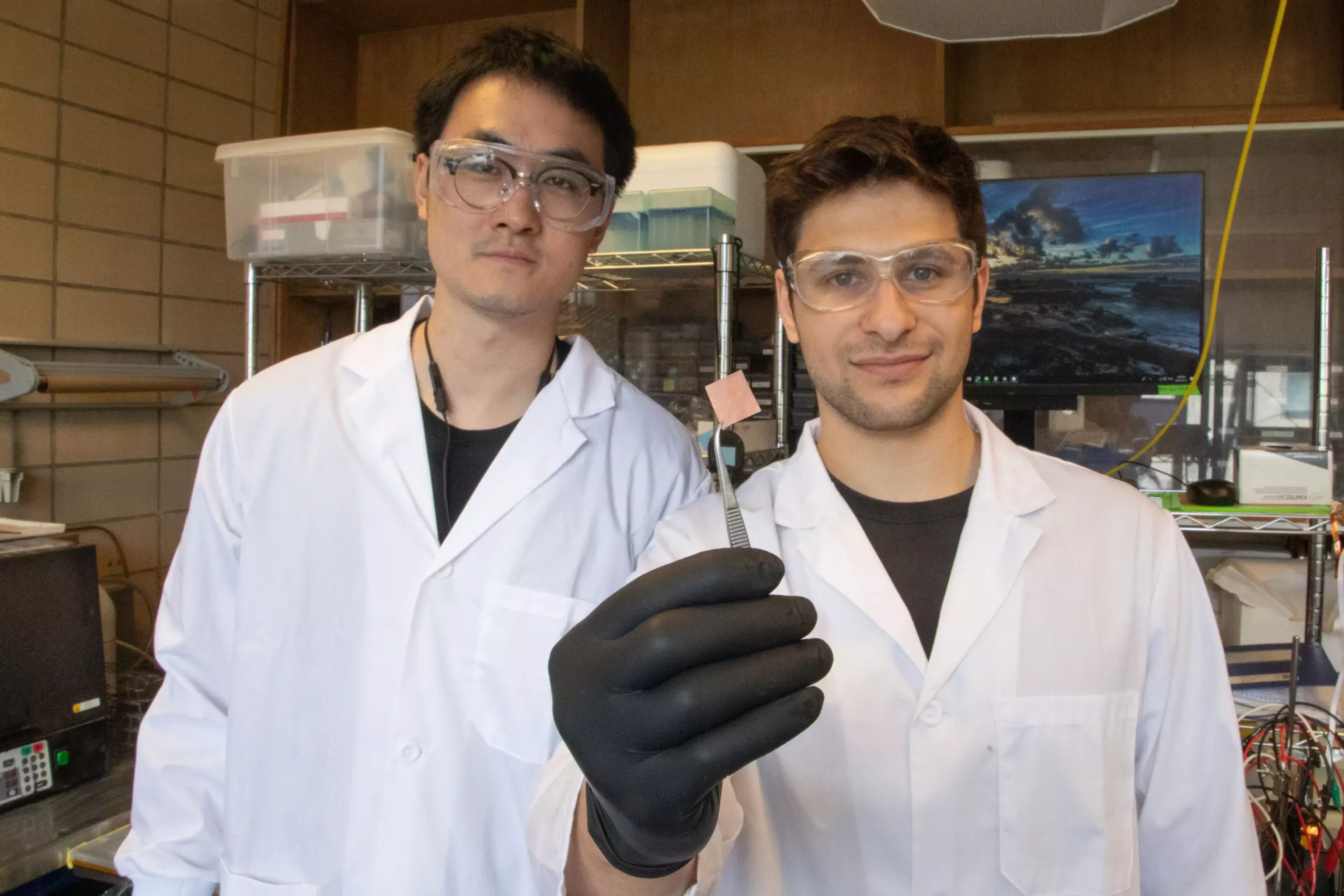

To address the issue of sulfur oxide poisoning, the research team implemented two key modifications to a standard copper-based catalyst. By adding a layer of Teflon to the catalyst surface, they altered the chemistry to inhibit SO2 reactions. Additionally, the introduction of Nafion, a conductive polymer, created a barrier that prevented sulfur oxides from reaching the catalyst surface. This novel design allowed the catalyst to maintain a Faraday efficiency of 50% for 150 hours, even when exposed to a mixture of CO2 and SO2 resembling industrial waste streams.

The success of this resilient catalyst sets a promising precedent for addressing other impurities present in carbon-rich exhaust streams. By focusing on a comprehensive approach to combatting chemical contaminants, the research team aims to expand the applicability of their innovative coatings to enhance the performance of existing high-performing catalysts. The potential to resist sulfur oxide poisoning opens the door to more efficient and sustainable carbon capture strategies without the need for extensive impurity removal processes.

The development of a robust catalyst that can withstand the challenges posed by contaminated carbon streams represents a significant advancement in carbon capture and utilization technology. This breakthrough paves the way for more cost-effective and practical solutions for reducing industrial carbon emissions and converting them into valuable products. With further research and development, the applications of this innovative catalyst design could revolutionize the approach to carbon capture on a global scale.

Leave a Reply

You must be logged in to post a comment.