In recent years, robots have been increasingly utilized for complex maintenance tasks. However, one of the major limitations of existing robots is their dependence on external power sources. This dependence greatly restricts their applicability in real-world scenarios. To address this issue, researchers from the Max Planck Institute for Intelligent Systems, Harbin Institute of Technology, and Hong Kong University of Science and Technology have developed a groundbreaking wireless miniature robot capable of moving through pipes and tubular structures without relying on external power sources.

Unlike previous wireless maintenance robots, the newly developed miniature robot is equipped with an internal power source and an actuation unit, allowing it to operate for longer periods without running out of energy. This innovative design enables the robot to cover longer distances within tubular structures, making it ideal for inspection, maintenance, and repair tasks in various industries including nuclear, industrial, and medical applications.

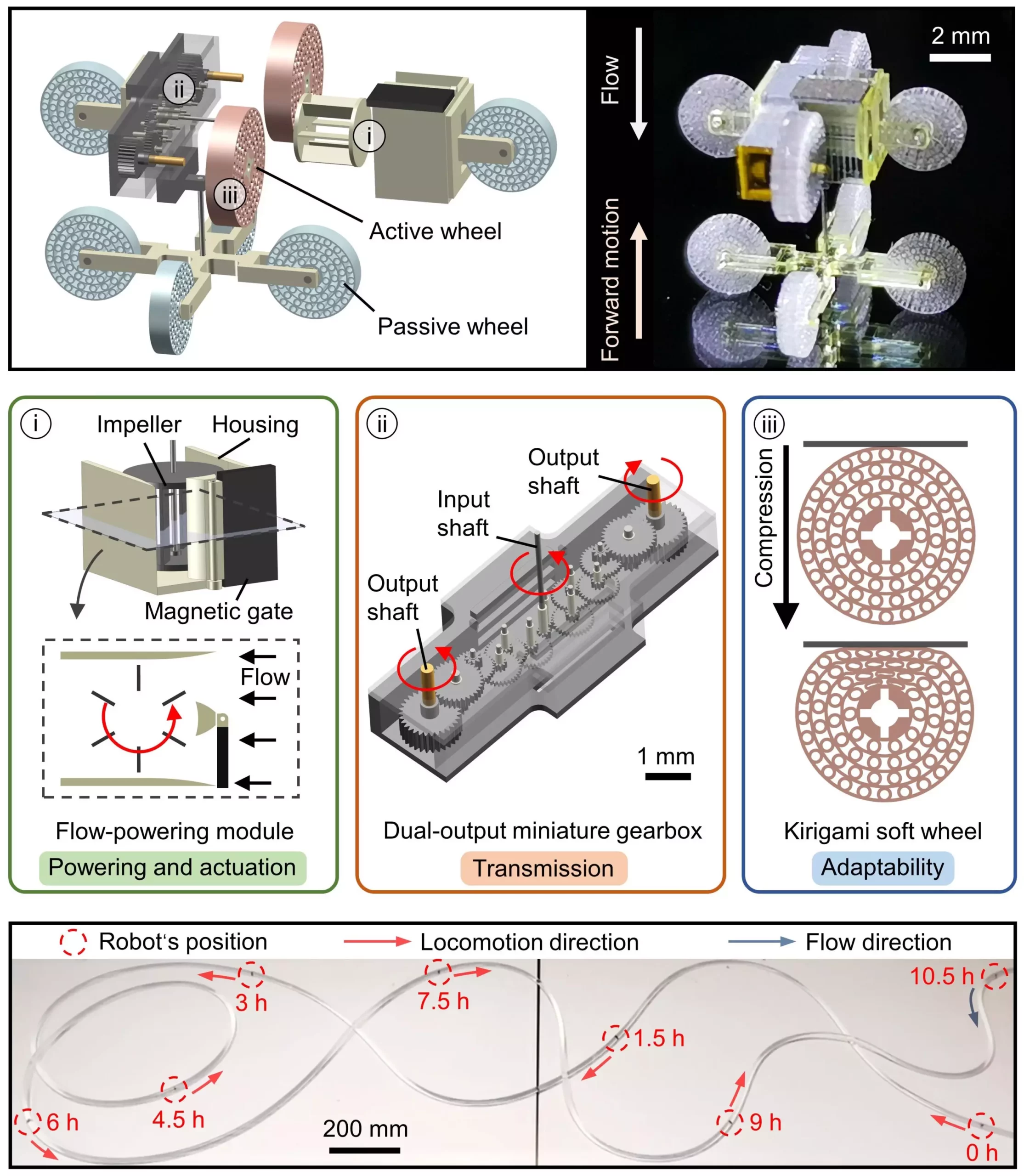

The robot incorporates three key components: a flow-powering module that utilizes flow power, a dual-output miniature gearbox for transmitting mechanical energy, and kirigami soft wheels for adaptive locomotion in complex tubes. The internal impeller of the robot converts fluid flow within the tubular structure into mechanical energy, allowing for seamless navigation through pipes. Additionally, the robot’s direction can be modulated using an external magnetic field, providing versatility in different environments.

The researchers conducted preliminary tests on the robot and achieved promising results. Moving forward, they aim to enhance the robot’s capabilities and stability to ensure its successful deployment in real-world settings. One of the key challenges they are addressing is the anchoring force needed to balance flow resistance on the robot’s body, particularly in high flow rate environments or on low-friction surfaces like oil pipelines. Techniques such as streamlining the robot’s body and adding microstructures to the wheel surfaces are being considered to improve locomotion efficiency.

The development of the wireless miniature robot for pipe maintenance represents a significant advancement in robotics technology. By eliminating the need for external power sources, this robot has the potential to revolutionize maintenance tasks in various industries. Its compact size and internal power source make it highly versatile and adaptable for navigating through complex tubular structures. With further research and development, this robot could become a valuable asset for maintenance professionals seeking efficient and effective solutions for complex maintenance challenges.

Leave a Reply

You must be logged in to post a comment.