Electric motors play a vital role in numerous applications across various sectors, from household appliances to advanced automotive systems. Despite each motor’s relatively modest energy consumption, their collective contribution can have significant implications for energy efficiency and sustainability. The burgeoning demand for eco-friendly solutions has led researchers and engineers to explore innovative designs that can maximize the efficiency of these crucial devices. A notable advancement in this field comes from Graz University of Technology (TU Graz), where a dedicated research team has developed a new generation of brushless electric drives aimed at reducing energy consumption in auxiliary automotive components.

The research initiative led by Annette Mütze has introduced several groundbreaking enhancements to traditional electric motor designs. One of the primary focuses has been on the integration of advanced control technologies, resulting in motors that not only consume less energy but also operate more quietly and are lighter in weight. These improvements make brushless integrated drives particularly suitable for applications such as pumps and fans, where efficiency is paramount. By modifying the current management system, the team has found a way to streamline the process of energy regulation, minimizing waste without compromising performance.

A significant breakthrough in this study was the reduction of “cogging torque,” which is a common issue in smaller motors. This torque causes unwanted vibrations and noise during operation. The team implemented innovative strategies including skewing and slotting the motor’s claws. This architectural refinement, executed at no extra cost, led to a substantial reduction in vibrations—approximately 70%. Mütze states that “this reduction proved crucial in enhancing both operational smoothness and noise control,” thus underscoring the importance of design in achieving superior motor performance.

Another notable advancement lies in the control of current flow. Traditionally, pulse width modulation (PWM) methods have been employed to regulate the energy supplied to electric motors. However, this conventional approach requires a multitude of switching operations, which generates additional energy losses. Mütze’s team’s new methodology significantly alters this paradigm, using a more efficient approach where motors are switched on and off only once per desired rectangle of current. This essential shift minimizes additional energy consumption, particularly evident at lower currents.

By reducing the frequency of switching operations, the requirement for components such as capacitors is also decreased by nearly half on the circuit boards, resulting in lower production costs. This efficiency not only leads to resource savings but can also render electric motors more economically viable for widespread use.

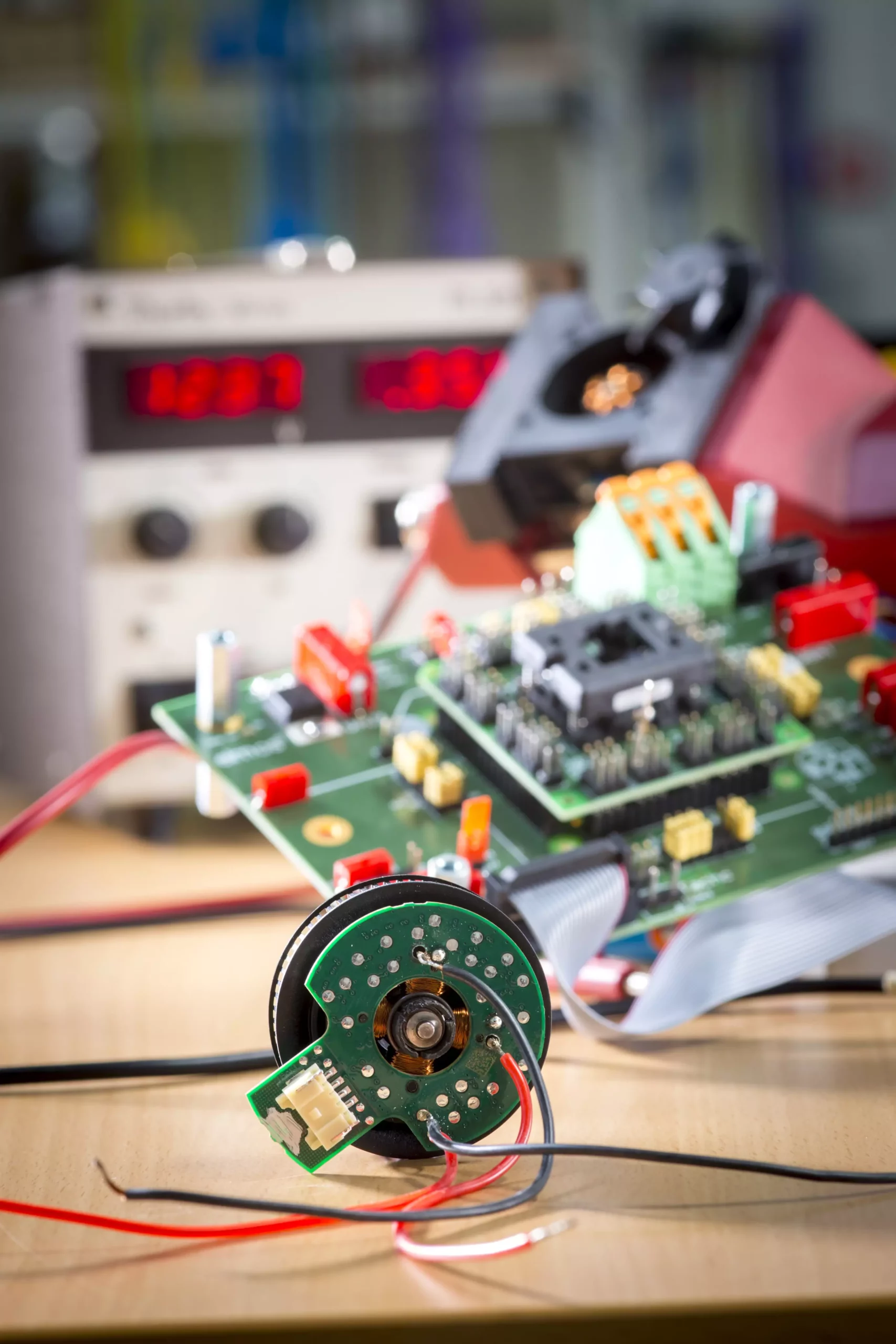

The introduction of printed circuit board (PCB) motors marks another pivotal advancement in the field of electric motors. In this configuration, the windings necessary for generating the magnetic fields are integrated directly into the printed circuit boards, paving the way for high levels of automation in manufacturing. This innovation is bolstered by the use of 3D-printed ferrite cores, which optimize magnetic flux guidance within the motor. These design improvements facilitate the deployment of more affordable ferrite-based magnets, further enhancing the motors’ cost-effectiveness and efficiency.

The combination of these innovations signals a transformation in how electric motors can be produced and utilized. Enhanced efficiency, cost savings, and reduced environmental impact are now more achievable than ever. Mütze’s research highlights the importance of interdisciplinary collaboration in driving forward technological advancements for sustainable solutions.

As the demand for sustainable energy solutions continues to rise, the advancements in brushless electric motor technology spearheaded by TU Graz represent a significant step forward. By focusing on innovative designs, streamlined control techniques, and advanced manufacturing methods, researchers are laying the groundwork for a new era of energy-efficient motors. The implications of these developments extend beyond just household and automotive applications; they promise to play a vital role in achieving broader sustainability goals. In this fast-evolving landscape, ongoing research and development will be essential to ensure that electric motors continue to meet the needs of a modern, environmentally conscious society.

Leave a Reply

You must be logged in to post a comment.