The quest for alternative energy storage solutions has brought sodium-ion batteries to the forefront of research and development. As the world seeks to reduce dependency on lithium, sodium presents a particularly compelling option due to its abundance and low extraction costs. Finding itself at the intersection of innovation and necessity, researchers have recently propelled sodium-ion batteries into the limelight through advancements in anode preparation technology. This article will explore a groundbreaking methodology pioneered by a research team that utilizes microwave induction heating for the rapid preparation of hard carbon anodes—critical components for enhancing the performance of sodium-ion batteries.

The Advantages of Sodium Over Lithium

Sodium, the principal element in table salt, is more than a thousand times more abundant than lithium, making it an attractive alternative for energy storage technologies. It boasts a lower reactivity level, which can enhance the electrochemical stability of batteries. As a result, sodium-ion batteries can potentially deliver improved performance in fast charging and discharging cycles, particularly in colder environments. Despite these enticing benefits, significant hurdles persist. The energy density and lifespan of sodium-ion batteries remain inferior to traditional lithium-ion variants. This situation prompts ongoing inquiries into material improvements and manufacturing efficiency.

Challenges in Anode Production

Anode materials are fundamental to the efficiency and capability of a battery, and sodium-ion batteries require hard carbon due to the larger size of sodium ions. Unlike graphite, commonly used in lithium-ion batteries, hard carbon is not naturally found; it must be synthesized through a complex carbonization process. This procedure requires heating hydrocarbon materials in an oxygen-free environment at temperatures that often exceed 1,000°C for extended durations. Not only is this process both economically and ecologically taxing, but it also stands as a formidable barrier to the wider adoption of sodium-ion battery technology.

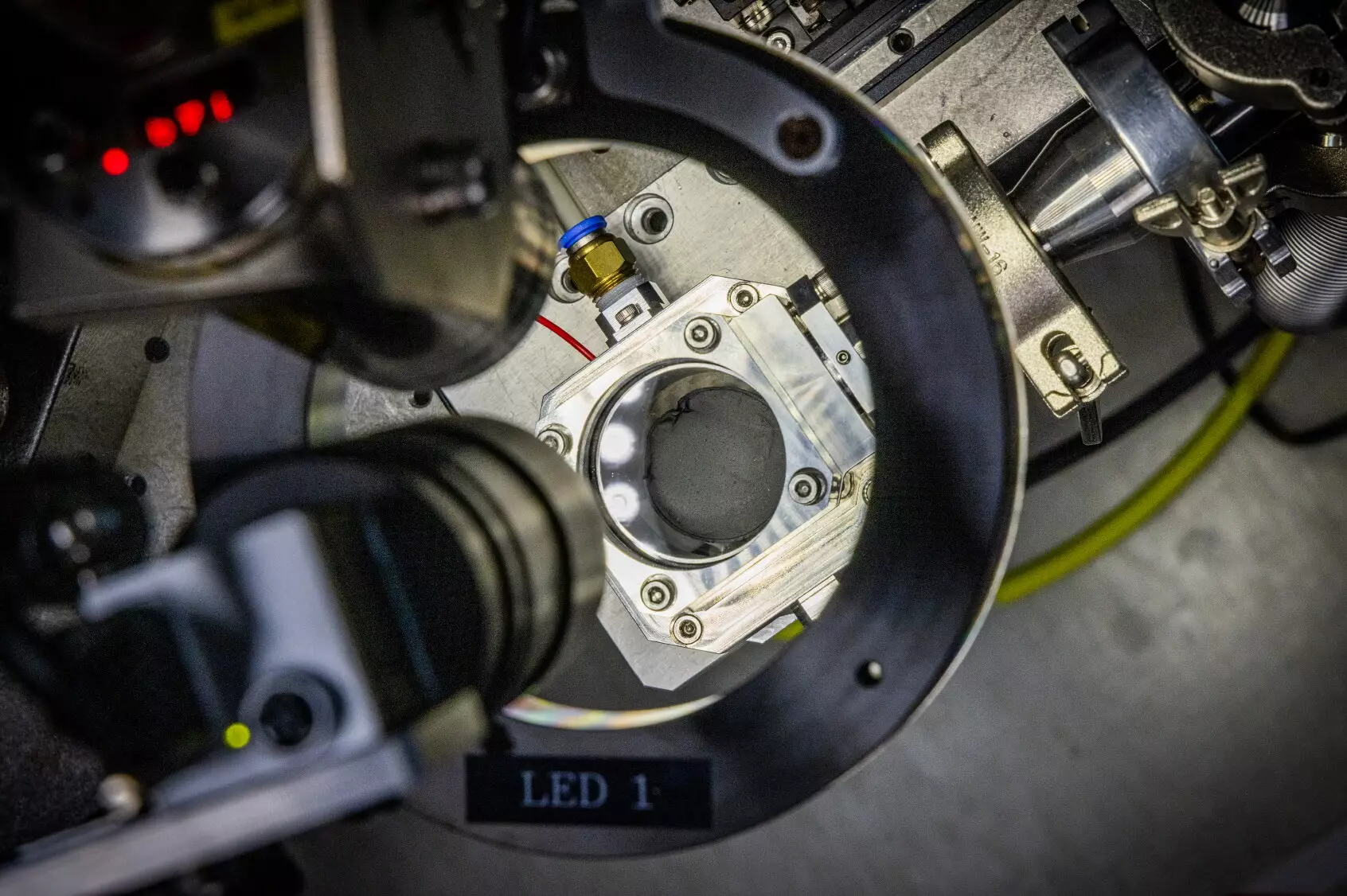

In light of these challenges, a team led by Dr. Daeho Kim and Dr. Jong Hwan Park has developed a novel approach using microwave technology that resembles the operation of a common kitchen microwave. They pioneered a method where films composed of polymers intermixed with highly conductive carbon nanotubes are subjected to a specialized microwave magnetic field. This process generates currents in the nanotubes, achieving temperatures over 1,400°C in a matter of seconds—specifically, just 30 seconds. This cutting-edge microwave induction heating representation not only reduces production time but also enhances energy efficiency.

The success of this innovative process is underpinned by the team’s use of a “multiphysics simulation” technique. This technique facilitated a comprehensive understanding of the intricate interactions occurring within the microwave magnetic field as it engages with nanomaterials. Through simulation, they were able to refine the preparation process for sodium-ion battery anodes, resulting in significant advancements in both performance and manufacturability. Published in the esteemed Chemical Engineering Journal, the research paper showcases collaborative contributions from student researchers who benefitted from the Korea Electrotechnology Research Institute’s (KERI) academia-research partnership program while highlighting the industrial relevance of the findings.

The implications of this research extend beyond sodium-ion batteries. The team envisions utilizing their microwave induction technology for other high-temperature applications, including all-solid-state batteries. They acknowledge the necessity to improve the performance of their anode materials further while also focusing on strategies to enable continuous mass production of large-area hard carbon films. This ambition suggests a future where sodium-ion battery technology could be commercialized on a significant scale.

Commercial Viability and Industry Interest

KERI has already sought to secure a domestic patent for this novel technique, anticipating substantial interest from companies engaged in energy storage materials. As the energy sector pivots towards sustainable solutions, the need for efficient, cost-effective battery options like sodium-ion technology is likely to explode. The potential for technology transfer agreements and industrial partnerships could drive forward the practical implementation of these innovations, marking a significant step in energy storage solutions that prioritize safety and performance.

The innovative microwave induction heating method designed for preparing hard carbon anodes represents a significant milestone in sodium-ion battery technology. With its rapid processing capabilities and reduced environmental footprint, this approach addresses some of the primary barriers inhibiting commercial viability. As the focus sharpens on sustainable energy solutions, such pioneering studies signify a critical turning point in how we approach battery production, ultimately paving the way for cleaner and more efficient energy storage options.

Leave a Reply

You must be logged in to post a comment.