In a groundbreaking research endeavor led by Dr. Sung Mook Choi of the Korea Institute of Materials Science, a new one-step electrode fabrication process has been developed for the first time in South Korea. Published in the prestigious journal Applied Energy, this innovative process revolutionizes the production of electrodes, a crucial element of anion exchange membrane water electrolysis, by directly manufacturing them from raw materials to a mass-producible level.

Key Findings

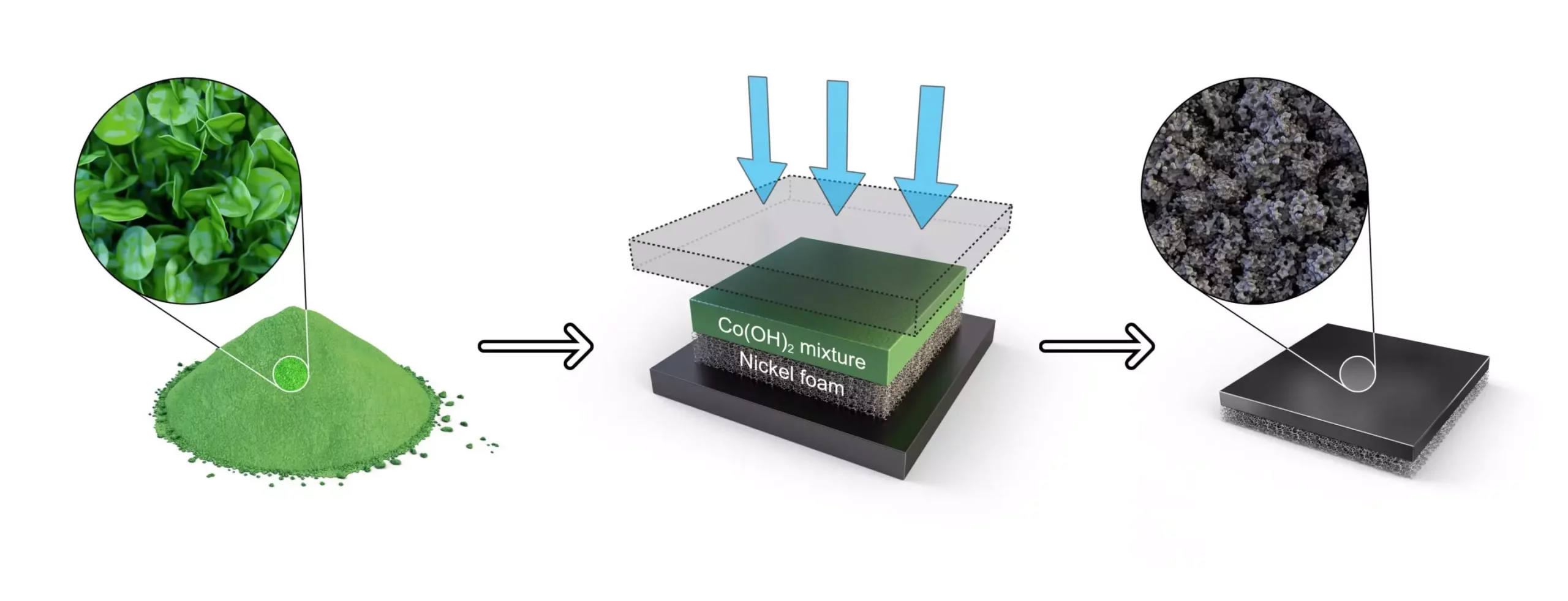

The research team successfully applied this one-step hot-pressing process to convert cobalt hydroxide into a cobalt oxide catalyst while simultaneously forming a highly uniform catalyst layer. This process eliminates the need for multiple complex steps involved in the traditional method, such as hydroxide-oxide-crushing-dispersion-coating-drying, and simplifies the process by 60%. Moreover, the technology significantly enhances the efficiency of hydrogen production and the durability during continuous operation.

To optimize the one-step electrode fabrication process, the research team meticulously fabricated a catalyst layer consisting of uniform oxide particles, each measuring 10 nanometers in size. This was achieved by carefully controlling the cobalt hydroxide slurry conditions, as well as the temperature and pressure parameters in the hot-pressing process.

The developed electrode was utilized to create a membrane electrode assembly (MEA) that integrated an anion exchange membrane and a hydrogen evolution catalyst. Its stability and performance were verified in a commercial-scale water electrolysis cell. By implementing this electrode in an anion exchange membrane water electrolysis system, the team showcased the potential for stable electrolysis with high hydrogen generation efficiency and low degradation rate.

Future Prospects

The emergence of green hydrogen production from water electrolysis is forecasted to reach significant milestones by 2030, with efforts underway in Korea to develop technology for a megawatt-level anion exchange membrane water electrolysis system. The goal is to commercialize such a system by 2030, leveraging the advancements made in the field. Currently, the domestic level of anion exchange membrane water electrolysis technology in Korea stands at 70-80% of world-class standards, calling for increased investment and localization efforts to secure a competitive edge in the global market.

Dr. Sung Mook Choi, the principal researcher, emphasized the significance of the one-step hot pressing electrode fabrication process in overcoming key challenges associated with the commercialization of anion exchange membrane water electrolysis. The technology holds immense promise in propelling advancements in water electrolysis technology, fostering localization, and seizing opportunities in overseas markets. Through continuous innovation and strategic collaborations, the future of anion exchange membrane water electrolysis appears brighter than ever before.

Leave a Reply

You must be logged in to post a comment.