As the world pivots towards renewable energy sources, the reliance on high-performance magnets has never been more pronounced. These magnets, ingrained in technologies like electric vehicles (EVs) and wind energy systems, depend on rare-earth elements (REEs) such as neodymium (Nd) and dysprosium (Dy). With their indispensable roles in creating highly efficient technologies, the spotlight is now on advancing recycling methods that can meet the burgeoning demand without the environmental costs of traditional mining. With this context, groundbreaking research from Kyoto University introduces a new recycling process that could redefine the landscape of rare-earth metal recovery.

Kyoto University’s Institute of Advanced Energy, under the leadership of Professor Toshiyuki Nohira, has proposed a novel method known as the Selective Extraction–Evaporation–Electrolysis (SEEE) process. This innovative approach smartly addresses the challenges associated with recycling Nd magnets—an area where traditional methods have often faltered due to inefficiency and heavy environmental impacts. Unlike conventional hydrometallurgical techniques that are both complicated and energy-intensive, the SEEE process simplifies the task, offering a green and effective alternative.

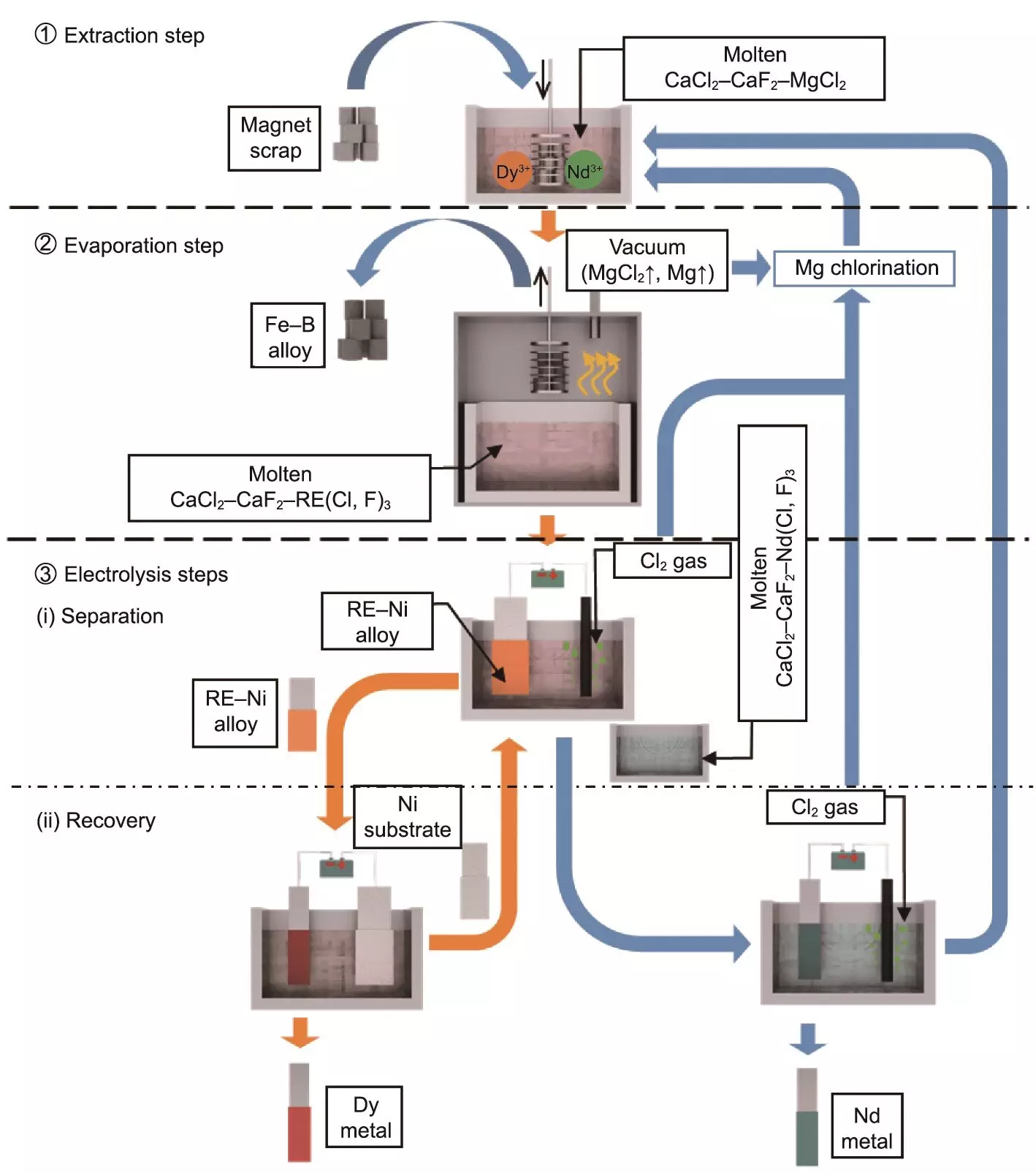

The SEEE process is composed of three distinct stages, each meticulously designed to enhance efficiency while minimizing environmental harm.

– **Selective Extraction:** The first stage relies on a molten salt mixture that not only extracts the desired REEs but does so with improved efficiency and reduced waste. By utilizing compounds like calcium chloride (CaCl2) and magnesium chloride (MgCl2), and enhancing it with calcium fluoride (CaF2), the process diminishes evaporation losses, which is a common pitfall in material recovery.

– **Selective Evaporation:** This stage streamlines the separation of remaining extraction agents and byproducts, allowing for a concentrated recovery of REEs.

– **Selective Electrolysis:** Finally, the process employs electrochemical techniques to separate the extracted metals based on their distinct formation potentials. This critical phase results in the retrieval of high-purity neodymium and dysprosium metals, integral for high-performance magnets.

Each of these steps exhibits attributes that make the SEEE process not just efficient but also a beacon for future recycling technologies.

The efficacy of the SEEE process is underscored by its impressive recovery rates—96% for Nd and 91% for Dy, each exceeding 90% purity. Such remarkable outputs present a significant leap forward compared to existing recycling methods, which have often struggled to achieve similar results. The implications are profound; as global demand for sustainable technologies, such as electric vehicles and wind energy systems, escalates, this process could seamlessly supply the necessary rare-earth elements without further straining natural resources.

Moreover, the SEEE process has the potential to mitigate environmental impacts related to new mining ventures, which often result in ecological degradation. By fostering effective recycling solutions, researchers at Kyoto University have positioned their method not just as a means of material recovery but as a strategy aligned with global carbon neutrality targets.

What sets the SEEE process apart is its versatility. While initially focused on the recycling of Nd magnets, there’s a belief among researchers that this method could be adapted for a wider array of applications, potentially even extending to the reprocessing of nuclear fuels. By branching out into other sectors that rely on REEs, the SEEE process could manifest as a critical tool in various industries, further amplifying its impact.

Nonetheless, despite the promising results, the Kyoto University team acknowledges the need for extensive technical evaluations to effectively transition this method into commercial applications. As research evolves, so too will the capabilities of this process, fostering a more sustainable future in material recovery.

The SEEE process exemplifies the convergence of advanced research and environmental responsibility. As we navigate through an era marked by escalating demands for renewable energy technologies, the role of innovative recycling methods like SEEE will become increasingly vital. By unlocking the potential of rare-earth elements through sustainable practices, we can not only support the continuing growth of high-performance technologies but also champion environmental sustainability, steering our planet towards a greener future. Thus, research initiatives such as those at Kyoto University catalyze a much-needed shift in various sectors—opening doors to a transformative recycling landscape that aligns with global ecological goals.

Leave a Reply

You must be logged in to post a comment.