When faced with challenges, we often seek complex solutions to address them. However, a recent study conducted by a research team at Pohang University of Science and Technology (POSTECH) sheds light on the effectiveness of a simpler approach to solving complex issues. The team, led by Professor Byoungwoo Kang and Dr. Abin Kim from the Department of Materials Science and Engineering at POSTECH, developed a new solid electrolyte that revolutionizes the field of solid-state batteries.

The Essence of the Issue

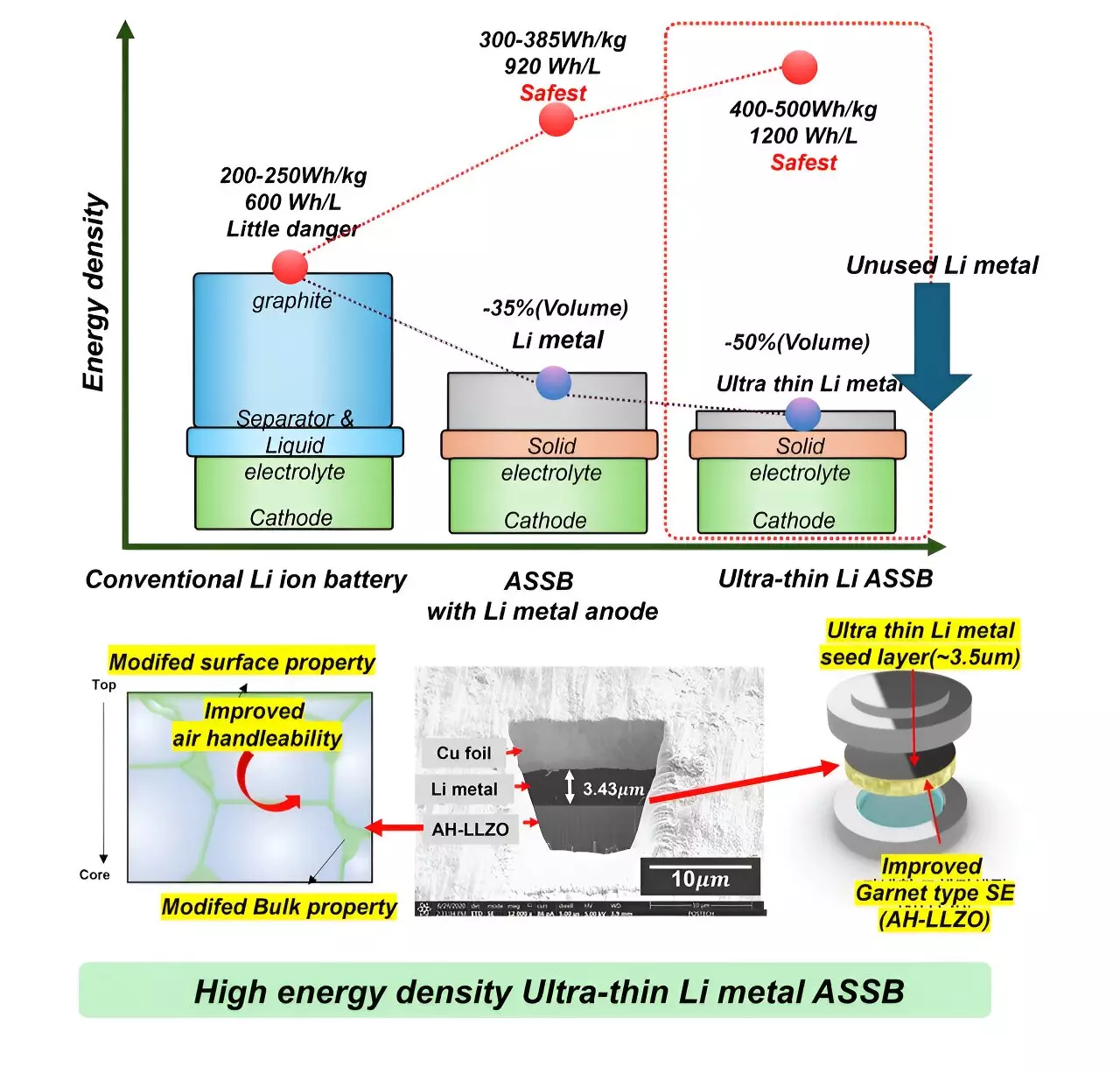

Solid-state batteries, which are considered the next generation of batteries due to their high energy density and safety, use solid electrolytes instead of liquids. Among the different types of solid electrolytes, the garnet-type oxide solid electrolyte (Li7La3Zr2O12, or LLZO) is highly sought after for its high ionic conductivity. However, LLZO is prone to forming a contamination layer (Li2CO3) when exposed to air, hindering its effectiveness in battery construction. Traditional approaches have involved coating the LLZO surface or using additional post-synthesis treatments to address this issue. While these methods have shown some improvement, they fail to completely eradicate the problem.

The research team at POSTECH took a different approach by focusing on enhancing the LLZO itself rather than relying on external coatings or treatments. Through their innovative air-handleable LLZO (AH-LLZO) technology, the team was able to prevent the formation of contaminant layers altogether. By creating a new hydrophobic compound (Li-Al-O) on both the surface and inside the material, the garnet-type solid electrolyte demonstrated enhanced contact with lithium metal, allowing for the development of ultra-thin lithium solid-state batteries.

The breakthrough achieved by the research team at POSTECH has significant implications for the field of solid-state batteries. By simplifying the process of inhibiting contamination layer formation and improving the contact with lithium metal, the team was able to create ultra-thin lithium solid-state batteries that are one-tenth the thickness of a human hair. This advancement not only reduces the amount of lithium metal used but also enhances the energy density of the batteries, making them lighter and more efficient.

Enhancing Practical Usability

The technology developed by the research team also allows for storage of the batteries in air without the need for special handling or facilities. This simplifies the process of using garnet-type solid electrolytes, making them more accessible and practical for a wider range of applications. Professor Byoungwoo Kang emphasized the significance of this research by stating, “We have solved the problem of LLZO’s inherent contaminant layer without the need for a post-processing step.”

The study conducted by the research team at POSTECH highlights the power of simplicity in addressing complex issues. By focusing on the core essence of the problem and developing innovative solutions, the team was able to revolutionize the field of solid-state batteries and pave the way for more efficient and practical energy storage solutions.

Leave a Reply

You must be logged in to post a comment.